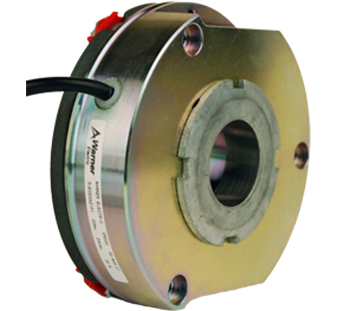

Find technical information about our Wide Range of Industrial Brakes

Industrial Brake Information

Select below for more information on our wide range of Industrial Brakes

The Basics

Spring applied brakes, also sometimes known as normally on brakes and failsafe brakes are most commonly encountered as electromechanical devices with DC current release actuation. When the supply current is interrupted the brake engages and remains on. This suits them to emergency stop and holding d…

More Info...Braking Torques

Spring applied brakes have catalogue rated torques. These are nominal figures and may require a small amount of running in before full torque is achieved. In particular a holding torque application without any dynamic friction may not achieve the rated torque. The required brake torque M (Nm) to…

More Info...Operating Conditions

Most spring applied brakes are designed for operation in dry conditions. Brakes should be protected from water, and particularly grease and oil which can cause a large drop in torque. Ambient temperature range is -20°C to +40°C. Below zero care should be taken to protect the rotor and armature plate…

More Info...Brake Switching

Spring applied brakes with DC coils can be operated from low voltage supplies, for example 12, 24, 36 and 48V DC. Switchgear should be sized for the relevant current. However many applications utilise an AC supply with a rectifier that converts to DC voltage. When switching the brake on the AC side…

More Info...